Past Projects Gallery

Technical Specialty Systems

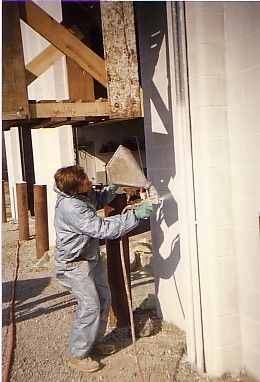

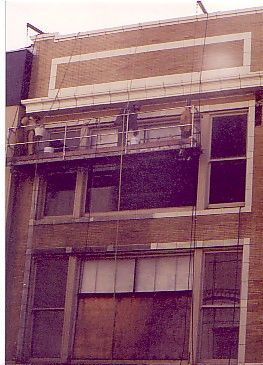

Stunning Examples of Our Restoration and Repair Services

Please take some time to peruse our gallery of past projects to get a feel for the type of mortar and concrete work that Technical Specialty Systems is known for in our industry. Turn to us for all of your concrete and masonry repair, cleaning, and restoration needs. Call today for service.

Some of our past projects include:

- Alliant Energy parking ramp

- Bank of the West

- Brucemore Mansion

- Cedar Rapids Community School District – masonry

- Cedar Rapids Country Club

- Cedar Rapids Five-in-One Dam – concrete repair

- Cedar Rapids Theater Building

- City Hall, Cedar Rapids IA

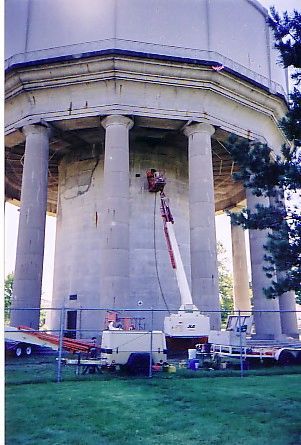

- City of Muscatine, IA – restoration of North Round Concrete Reservoir

- Grant Wood Building

- Guaranty Bank, Cedar Rapids, IA

- Iowa Medical Waste – caulking repair

- J Avenue Water Treatment Plant, City of Cedar Rapids, IA – masonry restoration

- Johnson County Administration Building – caulking

- Kingston Stadium, Cedar Rapids, IA

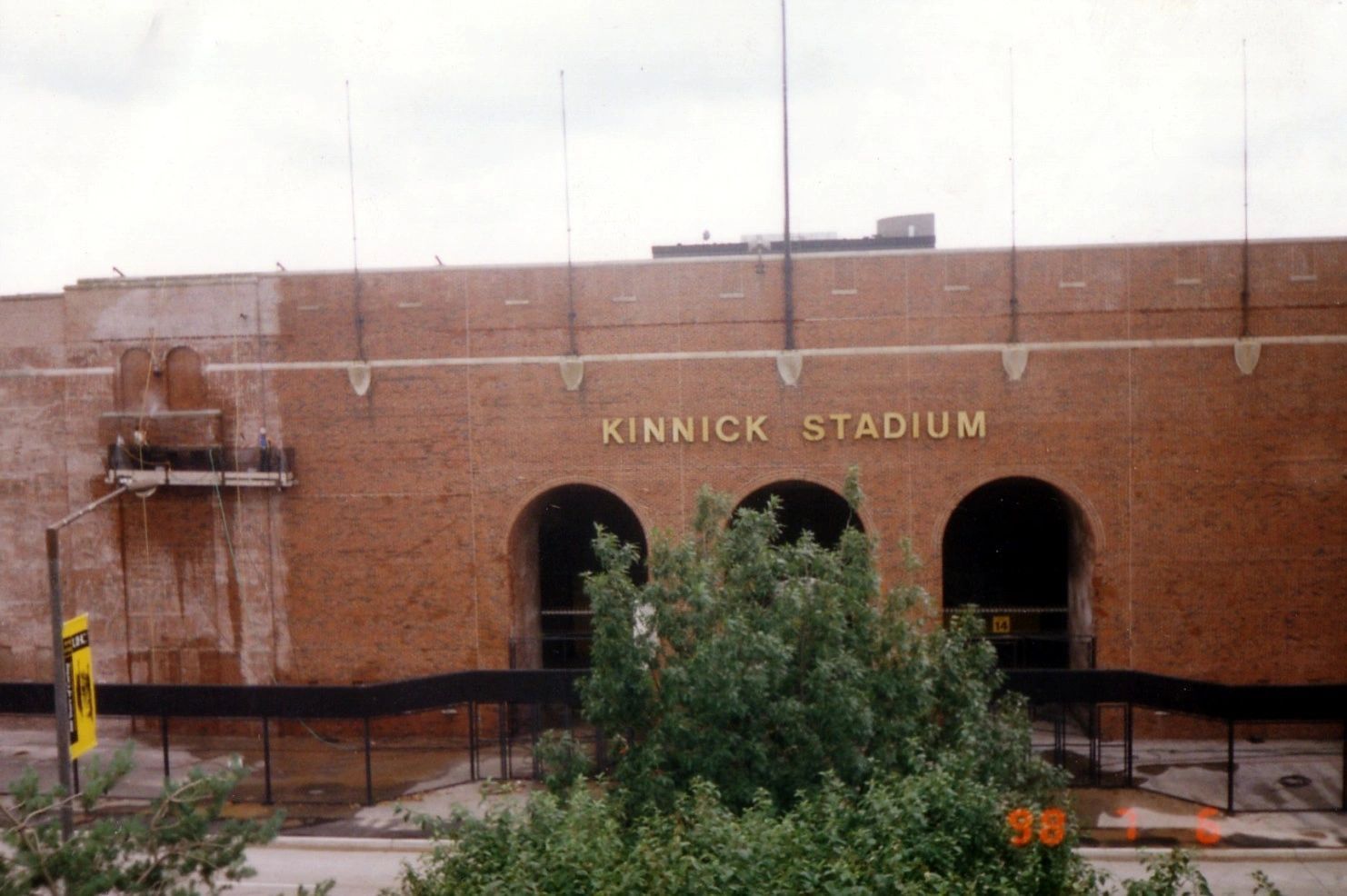

- Kinnick Stadium – Iowa City, IA

- Linn County Jail – masonry restoration

- Mays Island – ramp repair

- St. Luke’s Hospital – building restoration

- St. Luke’s Hospital – ramp repair

- Town Centre – parking ramp

- US Bank

- Wells Fargo

- Winnebago Motor Home Factory – caulking repair

Fairfield Football Stadium Project, Fairfield, IA

January 10, 2011

Ray Larson

Technical Specialty Systems

1115 Wenig Road NE

Cedar Rapids IA 52402

RE: On-Site Project Inspection

Project: Fairfield Football Stadium – Fairfield IA

To Whom It May Concern:

With reference to Ray Larson’s recent inspection of the above project this letter will summarize our discussion and recommendations. The purpose of the inspection was: (1) to determine the existence and extent of concrete deterioration at the stadium; determine the suitability of applying a waterproofing deck coating system; & (2) to make recommendations for repairs.

Background Information

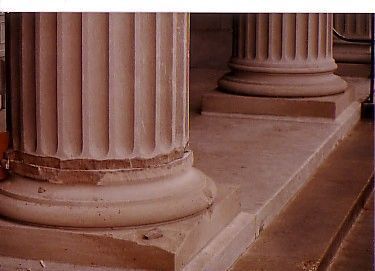

The concrete installed at the Fairfield Football Stadium is constructed on grade. Reportedly moisture is currently entering the cracks in the concrete surface resulting in concrete deterioration.

Without proper protection, exposed concrete can experience weathering conditions that can potentially result in concrete deterioration, spalling, & leaking. Left unprotected, destructive forces such as chemicals, water, and freeze/thaw conditions can result in cracks in the concrete. Moisture entering these cracks potentially can reach the reinforcing steel causing rust and corrosion which can lead to major deterioration of the entire structure. However, it is even more important to note that specific repairs need to be done as soon as possible to prevent the possibility of the trip and fall hazard to pedestrians resulting from the deteriorated concrete condition in the step areas.

Simply repairing the concrete spalled areas will not solve the underlying problem of moisture migration into the concrete. Without stopping the cause of the problem the new concrete repairs would likely eventually fail. An appropriate repair solution must be engineered to: (1) resolve the cause of the problem & (2) result in a long-term repair solution.

General Concrete Repairs and Repair Material Options

One of the purposes of this report is to specify proper repair materials for each area of concern. In addressing these repair areas we will discuss each of them in order. However, it is important to understand that all of the concrete repair areas should be properly prepared prior to application of the repair mortar. The following procedure should be followed: square cut all the edges of the repair area (minimum of 3/8 inch); remove all unsound concrete (minimum of ¾ inch around rebar); prime the cleaned rebar with MBT Zincrich Rebar Primer; base concrete should have a roughened profile (not smooth); dampen patch area with water (SSD – saturated surface dry); remove all standing water; apply a bond scrub coat; apply repair material; cure.

Observations / Inspection Notes

- Photo shows an overview of one side of the Fairfield stadium.

- Photo shows numerous areas of deteriorated concrete at a construction joint.

- Photo shows large concrete spall areas at a steep elevation.

Discussion

It is important to note that when applying a deck coating system to: (1) concrete on grade; (2) concrete installed over unvented metal pan decks; or (3) concrete decks containing between slab membranes, the standard application methods do not apply. The main concern is that moisture may be trapped under the coated surface of the concrete. Theoretically, it may be possible for this moisture and/or moisture vapor to expand, especially on a hot sunny day, resulting in the newly deck-coated surface to “bubble” or lose adhesion. The method of resolving the concern of installing deck coatings over concrete on grade consists of installing an epoxy vapor barrier system over the exposed concrete surface. Prior to the application of the epoxy coating, it would be required that the concrete surface pass a “black mat” moisture test (ASTM D4263).

As we discussed, each project may have special repair conditions to be considered such as: (1) Available downtime for repairs; (2) Temperature & moisture limitations for repair materials; & (3) Financial limitations for repairs. In addition, if a more in-depth analysis of this stadium structure is required, it may be appropriate to consult with a local structural engineer. In the case of the Fairfield Football Stadium the following repairs are recommended:

Repair Recommendations

- Remove the benches or cover the benches with plastic.

- Remove all loose & unsound concrete, & concrete repair materials.

- On overhead or vertical concrete repairs apply: MBT Gelpatch (Hand Apply) or Emaco S77 (Form & Pour), or Emaco S66 (Form & Pour).

- On horizontal concrete repairs apply MBT 1061 repair mortar (repairs over 1 inch in depth add aggregate).

- One option for repair of small concrete spalls (3/8 inch or less) on the concrete horizontal surface would be to apply Traficguard EP35 mortar (apply dry silica sand to refusal on the surface of the repair) prior to installing the deck coating system.

- Inspect existing concrete for cracks. Rout out cracks to a minimum of ¼ by ¼ inch & install NP2 sealant (tool flat & broadcast dry silica sand into the surface of the sealant).

- Remove all failed sealant & replace with NP2 sealant (broadcast dry silica sand into the surface of the sealant).

- Replace all failed sealant expansion joints with Sonneborn NP2 sealant (broadcast dry silica sand into the surface of the sealant). The width of the expansion joints should be a minimum of ½ to ¾ inch.

- Power wash all areas to be coated to remove contaminates from the concrete surface.

- Fill the larger holes in the vertical areas of the seating sections with NP2 sealant (broadcast dry silica sand into the surface of the sealant).

- Apply Trafficgard EP35 epoxy as a vapor barrier (90 square feet per gallon) & broadcast aggregate into the coating to refusal (the epoxy must have a rough sanded surface not smooth).

- Apply Sonneborn Sonoguard Pedestrian Deck Coating System in all seating areas: Sonoguard Top Coat (80 square feet per gallon + aggregate backrolled for slip resistance).

- Apply Sonneborn Sonoguard Heavy Duty Deck Coating System (sand to refusal) on the stair steps &, main walkways: Sonoguard Top Coat (80 square feet per gallon + aggregate to refusal, & Sonoguard Top Coat (80 square feet per gallon + aggregate backrolled for slip resistance).

Polyurethane deck coating systems provide a waterproof coating for vehicular and pedestrian traffic areas. They act as a complete barrier for moisture and salt penetration into the concrete surface. The slip-resistant surface is also an added benefit by increasing a slip-resistant safety finish to the coated concrete surface.

The Sonneborn Sonoguard system seals the concrete from moisture entry. It is applied as a liquid material which soon cures to form a waterproof elastomeric polyurethane traffic deck coating system designed for surfaces exposed to vehicular and pedestrian traffic. Properly applied, the system will provide a continuous, seamless, waterproof, skid-resistant protective coating.

Repair Option – Apply a 100% Solids Water Repellent

Instead of installation of a waterproof deck coating system [The best repair method], another option would be to apply Hydrozo 100 (a clear, breathable, high-performance, 100% silane sealer to all horizontal concrete surfaces in the stadium. It penetrates and seals out water & chloride ions. In addition, it penetrates deeply and chemically reacts with concrete to form an extra-long-lasting water-repellent surface. Application of Hydrozo 100 protects concrete from damage caused by chloride intrusion & extends the life of the structure. Coverage rate for Hydrozo 100 normally averages approximately 300 square feet per gallon.

In order to improve the aesthetics of the stadium, correct the current trip & fall safety concerns, and to ensure a water-tight surface, good maintenance practice would suggest that all of the above-noted concerns in this report be remedied as soon as possible. It is understood that all BASF products be applied as per their technical data sheets.

Over the past few years, there have been a number of local stadiums coated with the Sonoguard deck coating system. Projects include Kingston Stadium in Cedar Rapids Iowa; Brady Street Stadium in Davenport, IA and Augustana Stadium in Moline, IL. Enclosed are a few before & after repair photos of the Augustana Stadium project. It may be appropriate that representatives from the Fairfield Football Stadium inspect these facilities in order to see the advantages of applying the Sonoguard system.

BASF Building Systems offers products ranging from high-performance adhesives & sealants, wall & floor coatings, waterproofing membranes, and concrete repair products to expansion joints. There likely is a BASF product that will help solve your construction needs. BASF Building System’s multi-faceted problem-solving approach in creating products for the construction market is designed to not just “sell” products, but to promote solutions to construction problems and offer the best in a single-source supplier.

Share On: